ZHGAS (Chinese Academy of Sciences Hefei Gasification Technology Co., Ltd.), a national high-tech enterprise under the CAS Institute of Engineering Thermophysics (IET), originated from the Power Research Laboratory established by Dr. Wu Zhonghua in 1956. Today, IET stands as a leading strategic institute in "Power & Electrical Engineering" and "Energy Science & Technology." ZHGAS holds Class B Design and EPC Qualification for the chemical, petrochemical, and pharmaceutical industries. Leveraging 110+ core patents in CGAS (Circulating Fluidized Bed Gasification) technology, the company has delivered 40+ large-scale CGAS coal-to-gas projects, specializing in R&D, technology transfer, equipment supply, EPC turnkey contracts, and operations for clean industrial gas/syngas production from coal and biomass. Aligned with CAS’s mission of "Four Pioneering Goals" and "Three-Oriented Development," ZHGAS was selected for the 2017 CAS Hongguang Initiative (one of 10 projects nationwide) and awarded the CAS Science & Technology Promotion Prize.

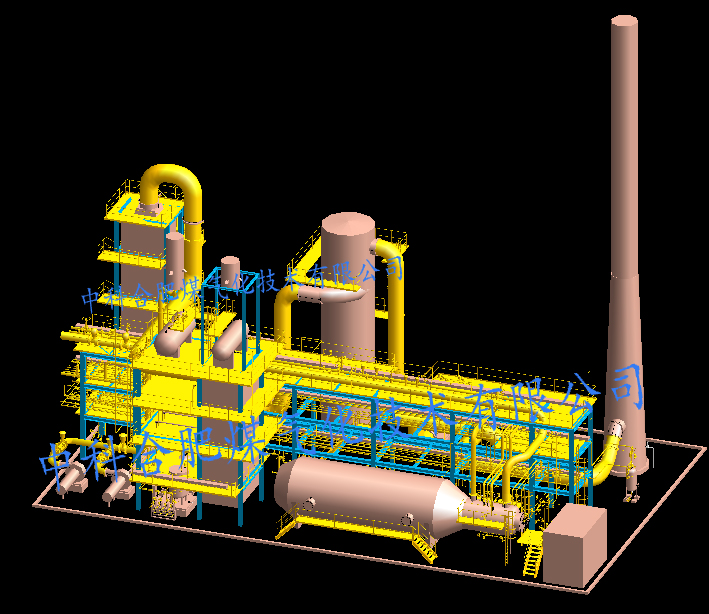

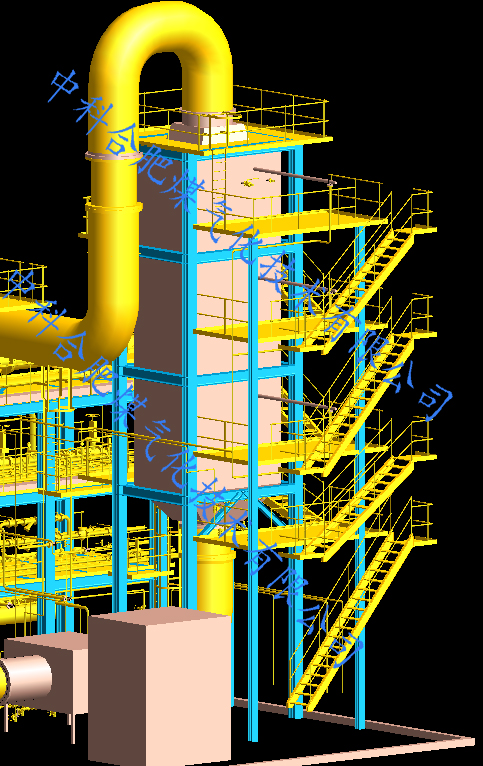

The company employs over 80 R&D and engineering design personnel, including 7 Professor-level Senior Engineers, 9 Senior Engineers, and 40+ doctoral/master’s graduates, covering product development, project management, and specialized fields such as process engineering, equipment design, piping systems, electrical engineering, and instrumentation. A rigorous design management system certified by China Quality Certification Centre’s ISO 9001 standards is strictly implemented, enforcing a designer-checker-reviewer system, unified design templates, optimized workflows, and enhanced precision through 3D modeling software.

Driven by innovation, the company has invested over RMB 30 million in R&D over three years through national/provincial projects (e.g., National R&D Program, Hongguang Initiative), focusing on technologies including ash melting for gasifiers, slagging prevention, gasifier operational diagnostics, and energy-saving solutions. These innovations deliver 1-2% efficiency gains, **>50,000-ton annual coal reduction**, and RMB 20 million+ cost savings for clients.

Services include feasibility studies, energy efficiency diagnostics, preliminary/detailed engineering design, automation control schemes, HAZOP studies, occupational disease/fire protection compliance designs, and safety implementation plans. Beyond standardized products, tailored solutions are developed based on client-specified coal gas applications (e.g., industrial fuel/chemical feedstock), coal grades, and steam/gas pressure parameters, serving industries like alumina, magnesium metal, nickel-iron, steel rolling, glass, ceramics, lime kilns, and syngas for ammonia/methanol production.

In addition to conventional EPC (Engineering-Procurement-Construction) and after-sales support, the company provides lifecycle upgrade services:

① Expert diagnostics & optimization: Remote monitoring + operational parameter adjustments to enhance gasifier performance;

② Coal adaptation: Dynamic parameter optimization for variable coal grades;

③ Technical retrofits: Low-cost, high-efficiency upgrade solutions from design to construction.

The company possesses proprietary Oxy-enriched Circulating Fluidized Bed (CFB) Gasification Technology with the following advantages:

Extensive Coal Adaptability: Suitable for low-rank coals (e.g., lignite, long-flame coal), "three-high" inferior coals (high-ash, high-ash-melting-point, high-sulfur), and low-reactivity coals (e.g., anthracite, lean coal), resolving challenges in coal selection, high procurement costs, and unstable supply

.

Flexible Gasification & Product Solutions: Through oxy-enriched air or pure oxygen gasification, it directly produces high-calorific fuel gas and chemical synthesis gas continuously and stably, eliminating the need for natural gas blending or gas separation to adjust composition

.

Serialized Gasifier Specifications: Covers industrial fuel gas and chemical feedstock gas production, with single-unit capacity of 10,000–100,000 Nm3/h. Also provides 5,000–50,000 Nm3/h gasifiers for biomass/sludge/waste gasification coupled with power generation

.

Integrated Design-Construction-Operation: Rapidly translates technical solutions into execution, reducing project cycles to 5–6 months for design, procurement, construction, and commissioning

.

Sustained Innovation & Upgrades: Offers full-lifecycle technical retrofits to help clients meet evolving energy-saving and environmental standards while enhancing product competitiveness

Advanced incineration technology processes hazardous waste gases/liquids from upstream chemical units, achieving **>99.99% destruction efficiency and compliance with national/EU emission standards (e.g., NOx < 50mg/Nm3). Systems prioritize operational safety, low maintenance, and compact footprint. High-temperature flue gas recovers steam via waste heat boilers, with thermal efficiency exceeding 85%**

.

● IPN Waste Incineration System: Processes 36,000 Nm3/h waste gas and liquids from isopropylidenediphenol production; co-generates 2.2 t/h S18 superheated steam.

● 35,000 t/a Solid Waste Incineration Project

● Waste Gas RTO (Regenerative Thermal Oxidizer) Project

● Bisphenol-A Waste Gas/Liquid Incineration System

By implementing the ISO 9000 series standards, the company has:

Enhanced quality and management awareness among all employees

Reinforced staff commitment to standardized processes and continuous improvement, aligning actions with customer-centric principles

Elevated overall operational management and quality control capabilities

Optimized monitoring mechanisms for project execution, ensuring rigorous compliance with regulatory and customer requirements

Achieved effective control over project progress, quality, and investment

Delivered turnkey projects with:

Shorter timelines

Lower costs

Higher returns

Superior quality

Driving maximum investment value for clients

Secured high client satisfaction and market recognition

Enabled clients to realize optimal ROI, resulting in high commendation and broad market acceptance.

By addressing national major needs and serving the main battlefield of the national economy, we focus on breakthrough strategic technologies and products with significant leading influence. Through technology integration, engineering development, and market application, we aim to yield major demonstration projects delivering substantial economic and social benefits.

Supported by the Hongguang Initiative, the Circulating Fluidized Bed (CFB) Gasification Technology has achieved extensive market influence. This technology has been deployed in 24 projects domestically and expanded overseas to serve Belt and Road countries, with its industrialization platforms experiencing robust development.